The R & D team of cegt center has developed a new waste PET degradation technology with independent intellectual property rights in view of the core problems existing in the traditional chemical recovery technology, such as harsh reaction conditions, long degradation time and complex separation and purification process, and successfully realized the establishment and operation of a thousand ton catalytic degradation waste PET industrial demonstration device. The monomer product obtained by degradation has high purity, which can be used not only for the production of food grade recycled PET, but also as the raw material for the preparation of high value-added products such as unsaturated resin and polyurethane adhesive. CAS process Institute has carried out many years of cooperation with foreign countries in the field of PET recycling. As early as 2012, academician Zhang suojiang / Director (director of cegt Center) visited Queen's University Belfast and visited Professor Martin Atkins of the school of chemical engineering. Later, Professor Atkins visited the process Institute many times and signed a cooperation agreement in October 2018. In 2019, the research team of the center carried out the optimization and amplification of pet cycle process in the UK. The two sides jointly carried out experiments in the laboratory of Wellington R & D center, and conducted depolymerization and recovery experiments with local pet samples in the UK, achieving the expected results. As the two sides have carried out substantive cooperation in the field of PET recycling and achieved outstanding results, Professor Atkins was received by Liu Xiaoming, Chinese ambassador to the UK, and won the international exchange medal. In April 2020, Professor Atkins wrote to inform that the recycled products obtained by using the Chinese PET recycling process have passed the test of alpek, the world's largest pet manufacturer, and the recycled PET meets all quality requirements. The two sides will jointly promote the international application of PET technology. The British side has started the preliminary engineering design of the 10000 t / a recycled PET production plant in Teesside, UK, and prepared 14000 tons of waste PET raw materials, with a view to providing 5000 recycled PET bottles for Coca Cola and P & G, and looks forward to promoting the construction of industrial production devices as soon as possible after the end of the epidemic.

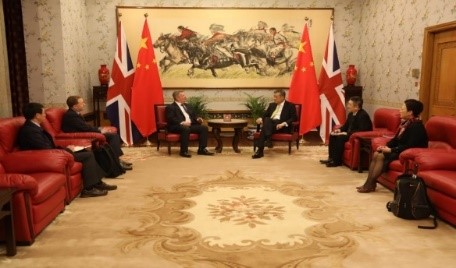

Partner Professor Martin was received by Ambassador Liu Xiaoming and received the medal of honor